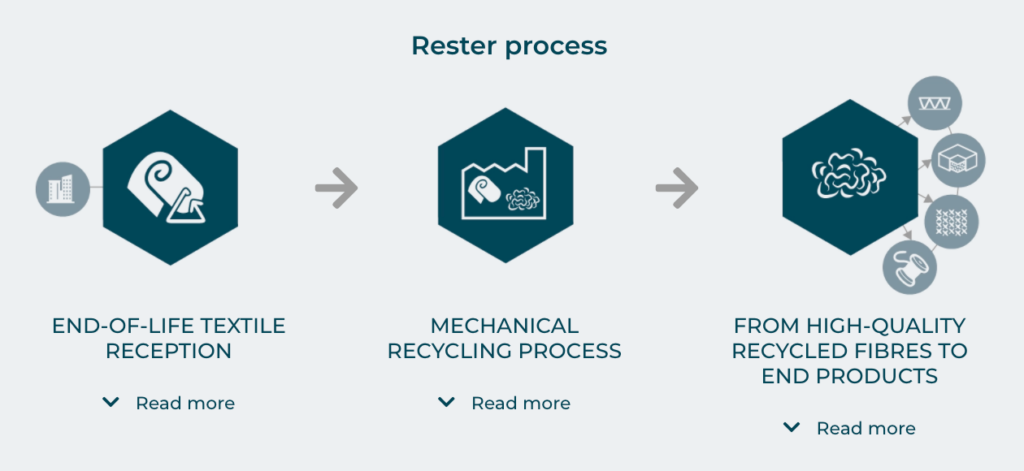

Rester uses the end-of-life textiles to make recycled fibre for the domestic textile and construction industry. Textiles are used in a wide variety of products, from clothes to furniture to air filters. For example, recycled fibres can be made into yarn, which can be made further into fabrics or technical textiles for the textile industry. The recycled fibre thus enables a fully domestic textile value chain from beginning to end. In the construction industry, recycled fibre is used for insulation material, acoustic boards, filter fabrics and composites.

Currently, the recycling plant in Paimio can process 6,000 tonnes of end-of-life textiles per year. In addition, Rester collaborates with Lounais-Suomen Jätehuolto, the company responsible for the management of consumer waste in South-East Finland. The shared goal is to process approximately 10 per cent of the textile waste generated in Finland.

In future, Rester wants to expand into international markets. For example, they are already piloting the processing of end-of-life textiles generated in the Baltic states and the Nordic countries.

//